JASO M610日本工业协会汽车零部件外涂层腐蚀试验方法

This standard specifies a test method for examining the cosmetic corrosion of metallic automotive parts and their surface treatments. It is cyclic in nature, i.e.; test specimens are exposed to changing climates over time.

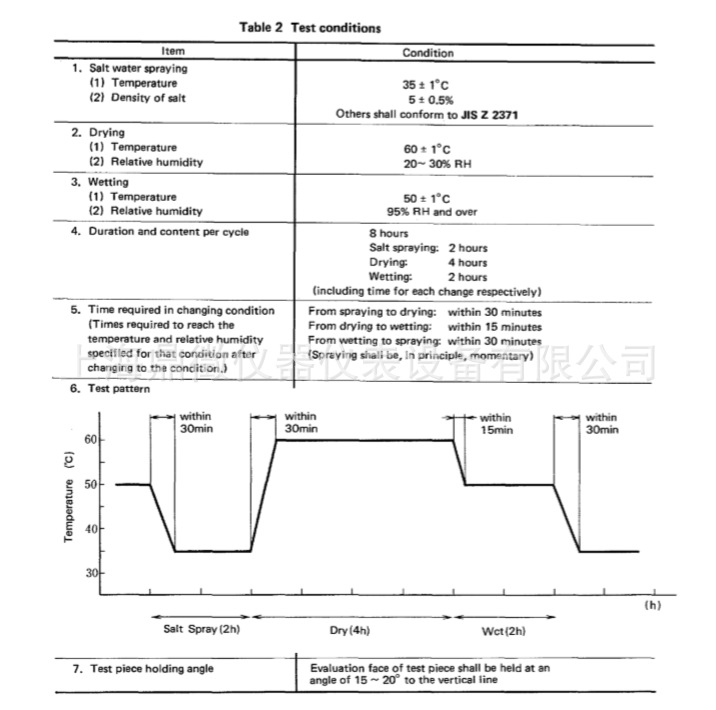

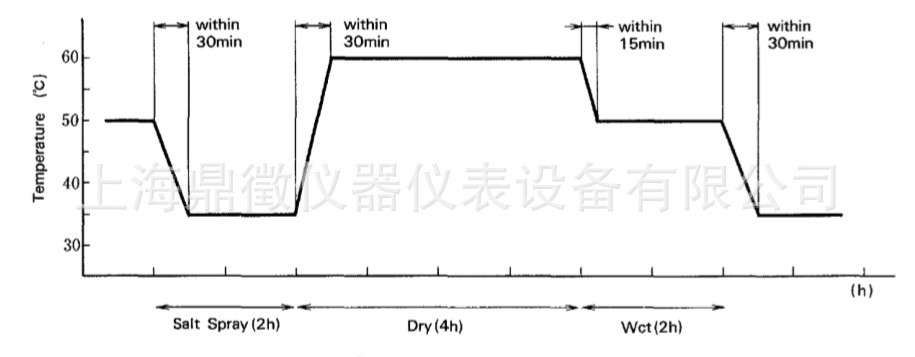

Test specimens are placed in an enclosed chamber and exposed to a changing climate that comprises of the following 3 part repeating cycle. 2.0 hours exposure to salt spray at +35C according JIS Z 2371. This is followed by 4.0 hours of air drying in a climate of 20 to 30%RH at +60C. This is followed by 2.0 hours exposure to a condensing water climate (wetting) of 95 to 100%RH at +50C. The number of cycle repeats and therefore the test duration is variable.

The maximum transition times between each part of the test cycle are also specified as follows:

From salt spraying to air drying within 30 minutes.

From air drying to wetting within 15 minutes.

From wetting to salt spraying within 30 minutes.

Please see elsewhere in this document for details of JIS Z 2371.

Chamber volumes of less than 400 Litres are not permitted by this test standard.

This test is also referred to as a Cyclic Corrosion Test, often abbreviated to CCT.

项目 | 名称 | 条件 |

1 | 盐雾测试 |

|

| 1、 温度 2、 盐水比例 | 1、 35±1 ℃ 2 、5%±0.5% 其他条件参考 JIS 2371 |

2 | 干燥 |

|

| 1温度 2湿度 | 1、 60±1℃ 2、 20~30% RH |

3

| 湿润(冷凝) |

|

| 1、温度 2、湿度 | 1、 50±1℃ 2、95% RH以上 |

5 | 周期持续时间和内容 | 8小时 盐雾:2小时 干燥:4小时 润湿:2小时 (包括每次变化的时间) |

6 | 改变条件所需的时间(在达到条件后达到所需温度和相对湿度所需的时间) | 从盐雾到干燥:30分钟内 从干燥到湿润:15分钟内 从润湿到喷雾:30分钟内 (原则上是瞬间喷洒) |

7 |

| |

8 | 试件夹持角 | 垂直线 15-20° |

Chamber volumes of less than 400 Litres are not permitted by this test standard.

内部尺寸小于400升的试验箱不允许通过该试验标准

QQ交流群

QQ交流群